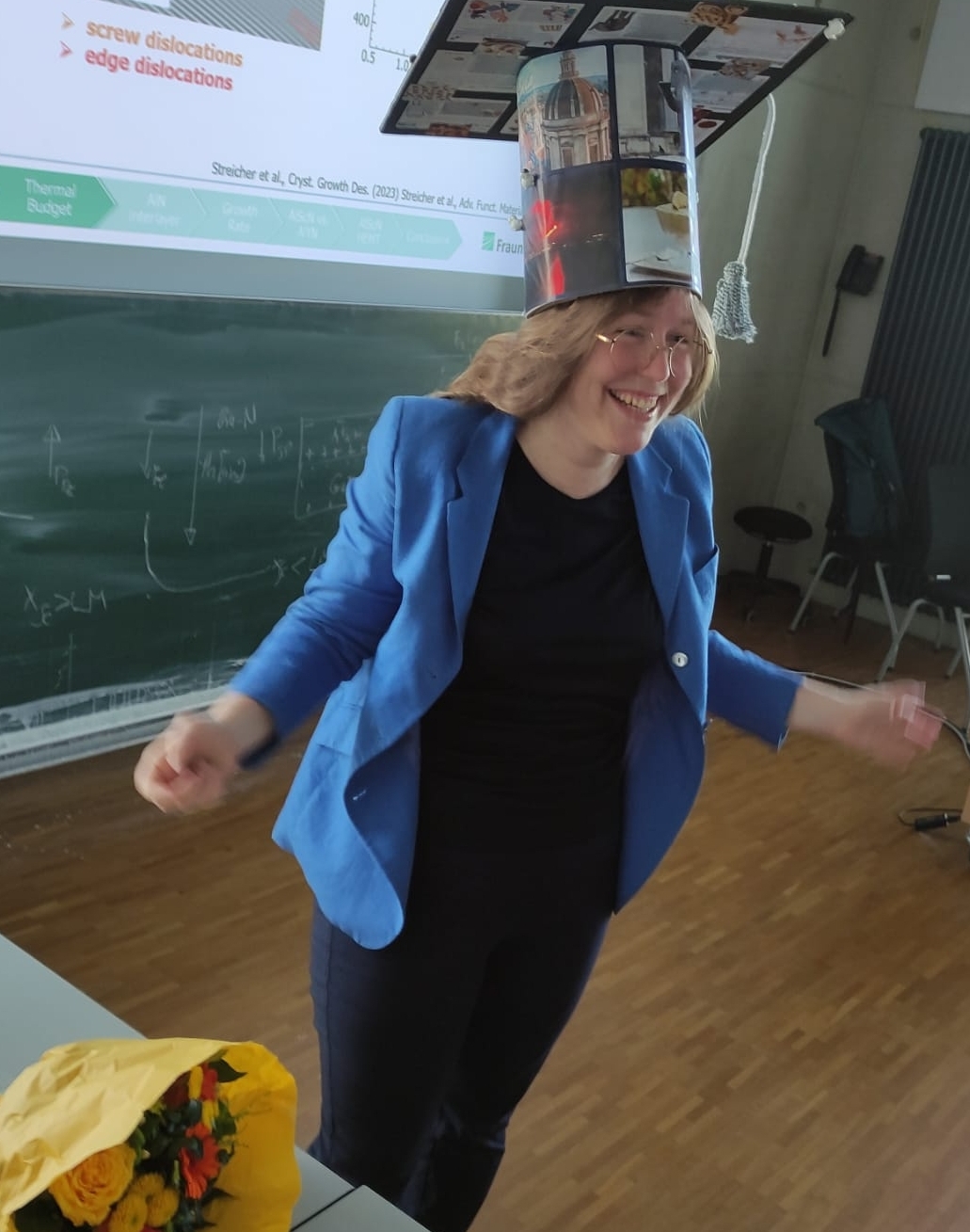

Dr. Isabel Streicher worked in the epitaxial nitrides group at Fraunhofer IAF until 2024 and received her doctorate with distinction. She can already look back on a time full of highlights in her young career as a researcher.

“The flexibility in material development at Fraunhofer IAF is truly exceptional.”

Interview with Dr. Isabel Streicher, who received her doctorate with distinction at Fraunhofer IAF

When did you come to Fraunhofer IAF and what did you do?

I came to Fraunhofer IAF in 2020 for my doctorate and researched the growth of aluminum scandium nitride (AlScN) with the epitaxial nitrides group. We were the first to produce the material by metal organic chemical vapor deposition (MOCVD). That was a sensation! The use of MOCVD opens up industrial applications for the material due to the scalability of the process. We later transferred our know-how from scandium to yttrium and grew the promising new semiconductor material aluminum yttrium nitride (AlYN) using MOCVD for the first time ever.

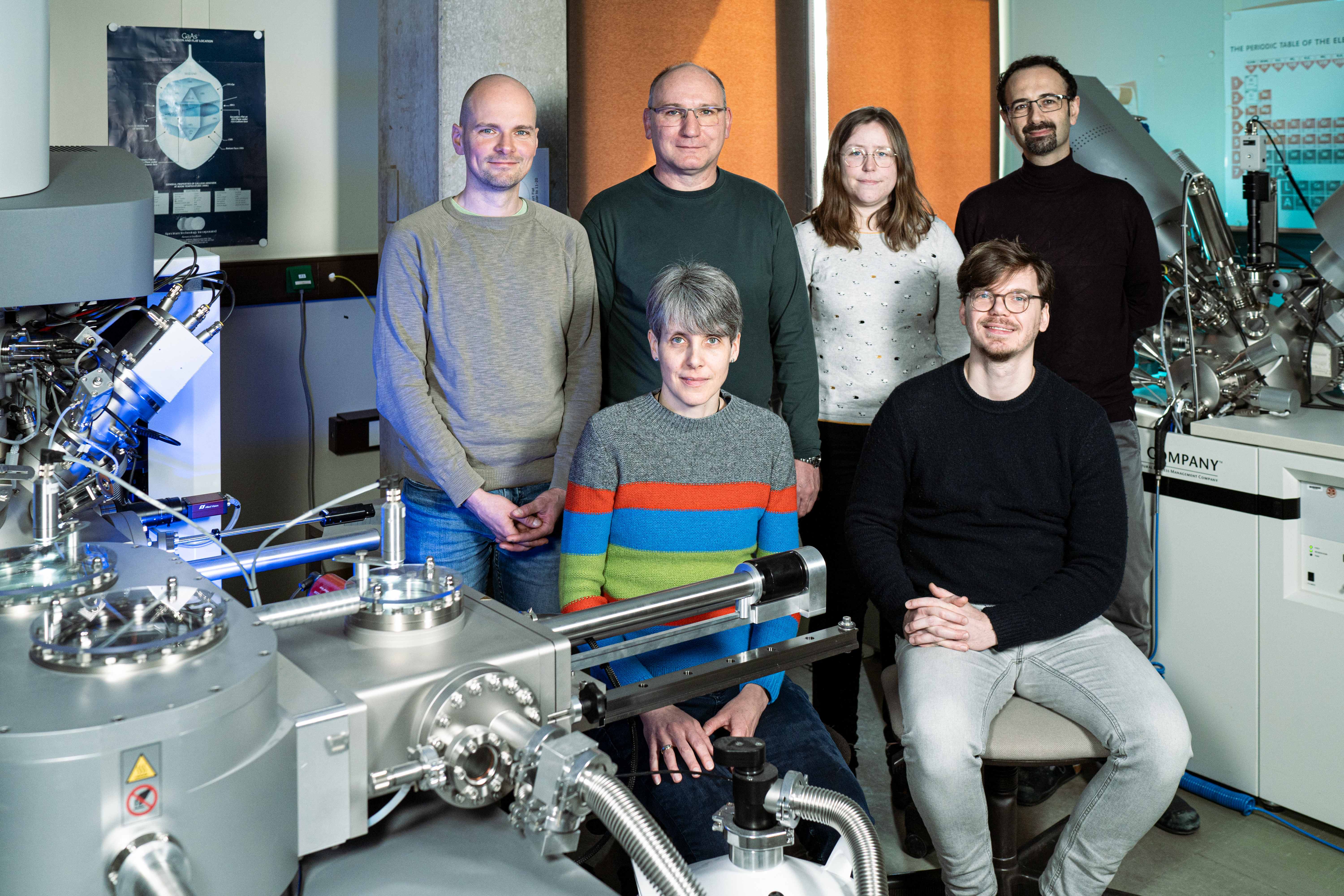

It was a very exciting time and I learned a lot: I attended conferences, published papers and received excellent support from my group leader Dr. Stefano Leone. Working with my group, but also across other teams from the institute, for example with structural analysis, was fun.

What is your dissertation about?

Due to their material properties, AlScN and AlYN have great potential for use in high-frequency and high-performance electronics for information and communication technologies. Power electronics based on these new materials promise, for example, to increase the performance of mobile radio stations while reducing energy consumption.

In my dissertation “Epitaxy of novel AlScN/GaN and AlYN/GaN heterostructures by metal-organic chemical vapor deposition,” I dealt with the new materials AlScN and AlYN as a basis for HEMTs (high-electron-mobility transistors). To be more precise, it was about the challenges associated with producing the new materials in industrially sufficient quality and productivity by MOCVD and introducing them into HEMTs.

How did you get into epitaxy?

I am interested in rocks and volcanoes, so I decided to do a Bachelor’s degree in Earth Sciences. During my studies, there was also a module on materials science with crystal growth, which I really enjoyed. That is why I decided to do a Master’s degree in Crystallography (Sustainable Materials—Crystalline Materials) at the University of Freiburg after my Bachelor’s degree. After graduating, I discovered the PhD position in epitaxy at Fraunhofer IAF. I was already familiar with the institute from the lecture given by Dr. Lutz Kirste, who is head of structural analysis at Fraunhofer IAF.

What were your highlights at Fraunhofer IAF?

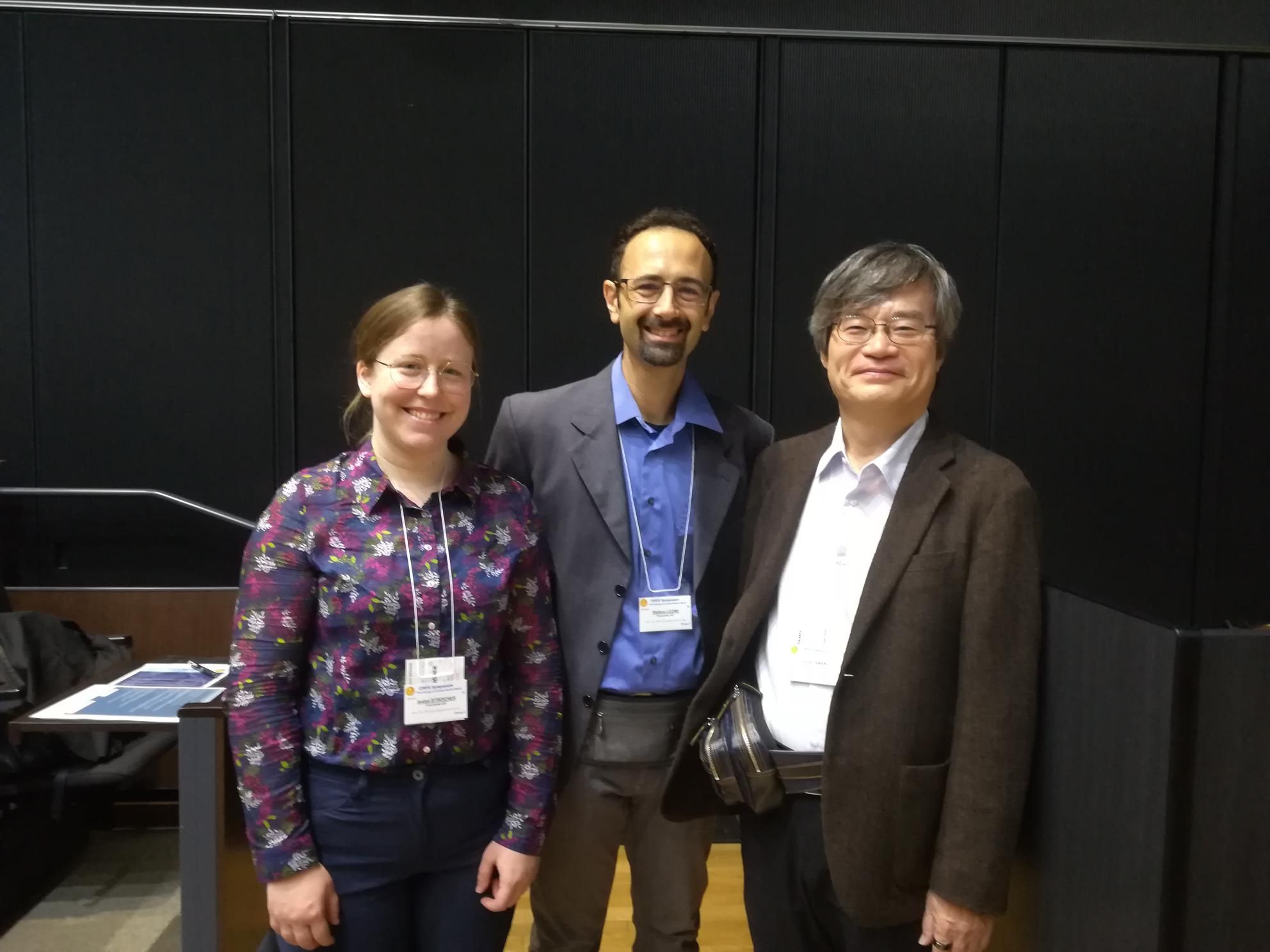

Definitely the growth of aluminum yttrium nitride, because it was something completely new and worked really well. Another highlight were my colleagues. It was always fun to go to work. A very special moment was also the last conference in Japan, when my colleagues and I met the Nobel Prize winner Prof. Dr. Hiroshi Amano and were invited by his research group to give a lecture on “Growth and structural characterization of nitride semiconductors at Fraunhofer IAF.”

Where are you now and what is your job there?

I am now working in Catania, Sicily, in Dr. Fabrizio Roccaforte’s research group at the National Research Council of Italy—Institute for Microelectronics and Microsystems (CNR-IMM), which is known by experts for its GaN processing. I would like to develop my skills in the field of processing there. I also like Italy and the volcano Etna is of course also very interesting for me. This actually brings me back full circle to my origins in the geosciences. During my first days in Catania, it was fascinating to find the volcano’s ash on the balcony in the morning, but it’s just everywhere and after a while it’s not so great anymore (laughs).

I will definitely stay in touch and would be happy to set up a joint project with Fraunhofer IAF. The institutes have different measurement methods and could complement each other well.

What does Fraunhofer IAF have that others do not?

The flexibility in material development is truly exceptional. This allowed me to try out many new things that required a lot of development work at the beginning. This would not have been possible in industry. Collaboration with partners is also very much encouraged. I was, for example, able to work very with various universities and other Fraunhofer Institutes.

Fraunhofer Institute for Applied Solid State Physics IAF

Fraunhofer Institute for Applied Solid State Physics IAF